Pharma 4.0: How Digitization is Transforming Manufacturing Operations

The pharmaceutical industry is undergoing a profound transformation, ushered in by the era of Pharma 4.0—a concept that integrates digital technologies into every facet of drug manufacturing. Inspired by the broader principles of Industry 4.0,

The pharmaceutical industry is undergoing a profound transformation, ushered in by the era of Pharma 4.0—a concept that integrates digital technologies into every facet of drug manufacturing. Inspired by the broader principles of Industry 4.0, Pharma 4.0 goes beyond automation to create an intelligent, interconnected ecosystem where machines, data, and human decision-making coalesce in real-time. The result? Smarter, safer, and more efficient pharmaceutical production.

From Legacy to Intelligence: The Digital Shift

Traditional pharmaceutical manufacturing has long been constrained by batch-based operations, siloed data systems, and time-consuming quality assurance protocols. Digitization offers a radical departure from these limitations, replacing manual processes with data-driven, agile systems that adapt in real-time.

Key drivers of the digital shift include:

- Increased regulatory scrutiny demanding traceability and data integrity

- Rising pressure for faster time-to-market, especially post-COVID

- Cost efficiency through predictive maintenance and process optimization

- Demand for personalized medicine requiring flexible, small-batch production

Core Technologies Powering Pharma 4.0

- Industrial Internet of Things (IIoT)

Sensors embedded in machinery and production lines gather real-time data on temperature, humidity, and equipment performance. This enables predictive maintenance, reducing downtime and increasing operational continuity. - Digital Twins

Virtual replicas of physical systems simulate, monitor, and optimize production processes. These models can predict the outcome of process changes before implementation, reducing risk and waste. - AI and Machine Learning

AI algorithms analyze vast datasets to optimize formulations, detect anomalies, and refine quality control. Machine learning models continuously improve by learning from new data inputs, enhancing accuracy over time. - Cloud and Edge Computing

Cloud platforms store and analyze centralized data, while edge computing enables real-time decision-making at the production site, minimizing latency and enabling decentralized operations. - Advanced Analytics

From process analytical technology (PAT) to real-time release testing (RTRT), analytics are now deeply integrated into production to ensure consistent product quality and regulatory compliance.

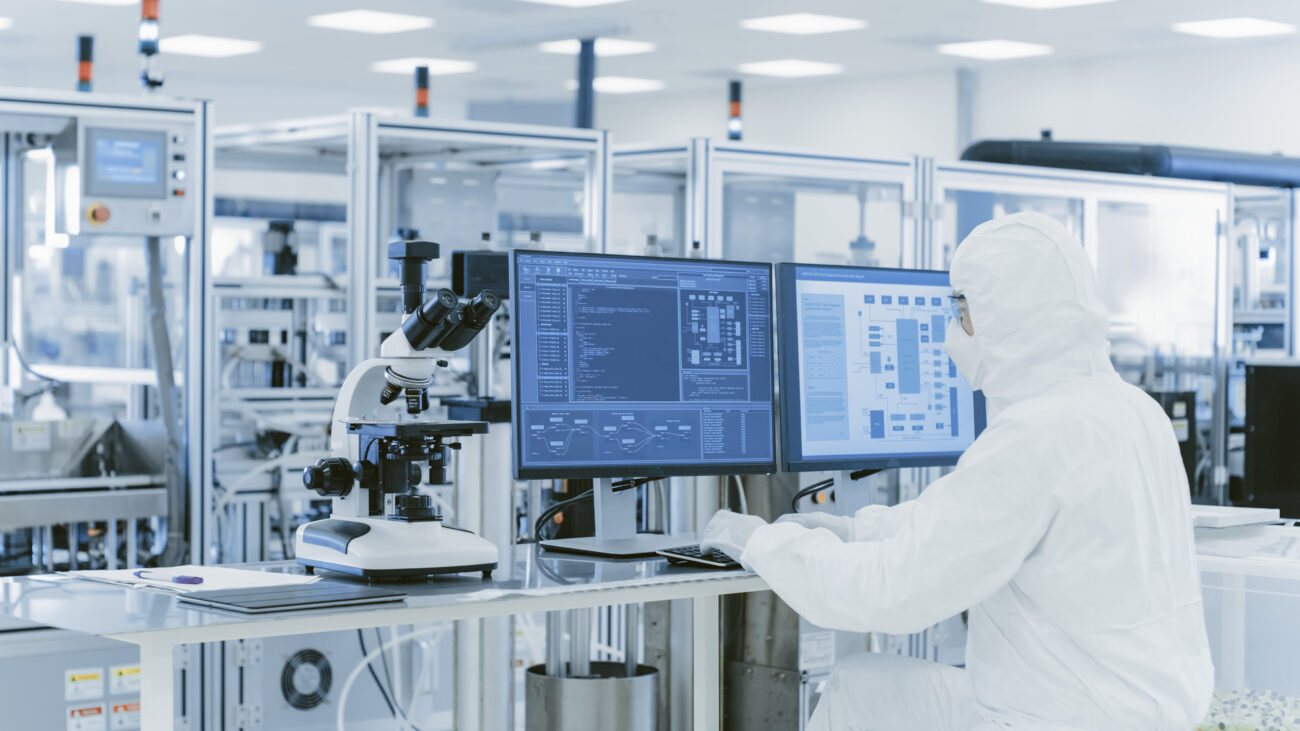

The Smart Factory: A Glimpse into the Future

In a Pharma 4.0 smart factory, systems are fully integrated across IT (information technology), OT (operational technology), and business layers. Here’s what that looks like:

- Automated production lines that adjust parameters on-the-fly

- AI-powered dashboards offering insights for proactive decision-making

- Seamless MES-ERP integration ensuring data continuity from shop floor to top floor

- Digital quality control with real-time documentation and audit readiness

Such environments not only accelerate batch release but also enhance transparency, collaboration, and sustainability.

Human Role in a Digital World

Pharma 4.0 is not about replacing humans but augmenting their capabilities. The future workforce will require cross-disciplinary expertise—combining pharmaceutical knowledge with data science, digital literacy, and system engineering. Upskilling and change management are therefore crucial components of successful digital transformation.

Regulatory Alignment and Compliance

Regulatory bodies like the FDA and EMA are increasingly supportive of digitization, provided it enhances product safety and traceability. Initiatives like the FDA’s Pharmaceutical Quality for the 21st Century and ICH Q12 guidelines align well with Pharma 4.0 principles, encouraging adaptive and continuous manufacturing.

Challenges Ahead

Despite the promise, several hurdles remain:

- High upfront investment in technology and training

- Data security and cyber-risk in interconnected environments

- Resistance to change among legacy workforce

- Interoperability issues between new and old systems

Successful transformation requires a clear roadmap, stakeholder buy-in, and a phased implementation strategy.

A Digital-First Future for Pharma

Pharma 4.0 is not a destination but a journey—one that reimagines manufacturing as a dynamic, intelligent system capable of responding to evolving market and regulatory needs. Companies that embrace this transformation will be better positioned to deliver high-quality medicines faster, more efficiently, and at lower cost. The digital revolution is here—and it’s reshaping the very DNA of pharmaceutical manufacturing.